Microprocessor based Automatic Tissue Processor is designed to prevent a solution to the rapid processing of tissue in Histology Laboratories. MPTP removes all the water from a tissue sample &replace it with paraffin wax with optimum speed to curtail damage to the tissues caused by dehydration and shrinkage.

SALIENT FEATURES – Operated by feather touch keyboard with digital display shows: Real time. Date, month and year. Wax bath temperature: set temperature & attain temperature Station No. is displayed In which Tissue basket is running.station time and lapse time shown on display.

Tissue processor with programmable logic controller for complete cycle. Timing & stage sequence, Wax Bath temperature safety system etc. all controlled/operated by feather touch key board with Digital display. The instrument capable to retain data in case of power failure. It has front panel with the key board, digital display and control switch. It has PID temperature controller to control the wax bath temperature.

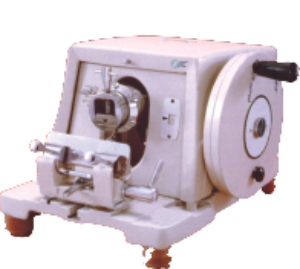

The heavy duty base provides absolute support for mechanism and knife holder. Aluminium cover is hinged to the base, protect the interior parts and opens to provide easy access for cleaning & lubrication.

AUTOMATIC FEED RELEASE WITH AUTOMATIC SAFETY DEVICE – Total feed excursion is 28 mm. When the limit of the feed is reached, a safety device automatically disengages the feed mechanism

FRONT-POSITIONED FEED INDICATOR WITH LATEST CAM DRIVE – The feed indicator graduated in microns is conveniently located at front of the instrument and feed setting from 1 to 50 microns in steps of 1 micron each is controlled by a knurled knob at the back of the microtome. The sturdy knife holder in addition to the knife elevating and leveling adjustments provides lateral movements for complete use of knife edge. The angle adjustable upto 30@ is indicated on a reference scale. streamlined Razor 120 mm made from highest quality fine grain tool steel which is heat treated and tested for micro structure is furnished with the instrument

Cryostat microtome is a most modern and dependable for frozen sectioning in diagnostic and research laboratories very simple to operate, reliable, precise instrument.

You can precisely control the temperature of your specimen for ideal sectioning fitted with built in automatic voltage stabilizer. Cryostat microtome with digital temperature controller cum indicator. Temperature range upto -30⁰C and -40⁰C.

We Strictly Follow the privacy policy as follows:- We don’t ask you for personal information unless we truly need it. We believe the importance of Privacy Policy. (We can’t stand services that ask you for things like your gender or income level for no apparent reason.) We don’t share your personal information with anyone except to comply with the law, develop our products, or protect our rights. We don’t store personal information on our servers unless required for the on-going operation of one of our services.

We Strictly Follow the disclaimer policy as follows:- All views expressed on this site are my own and do not represent the opinions of any entity whatsoever with which I have been, am now, or will be affiliated.

Khera© 2024 All Rights Reserved